UNIVERSAL PARTS

>

NITROUS, METH & FUEL

>

|

|

AEM WATER/METHANOL INJECTION KIT (BOOST-DEPENDENT UP TO 35 PSI)

|

30-3300 is now available on our new website!

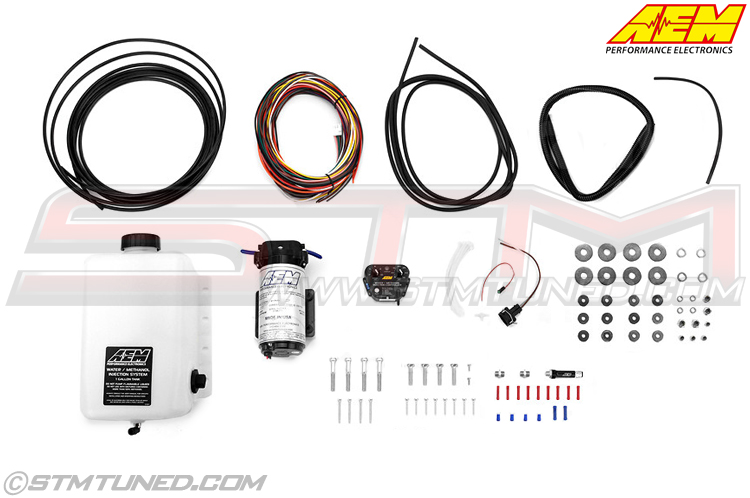

AEM Water/Methanol Injection Kit for Forced Induction Gasoline Engines (Up to 35 PSI)

Fits these Applications:

Universal Product

Part Number:

30-3300

The AEM controller with kit 30-3300 is boost dependent for forced induction vehicles up to 35 PSI of boost and has an on-board manifold absolute pressure (MAP) sensor with a molded-in nipple for a boost hose pickup.

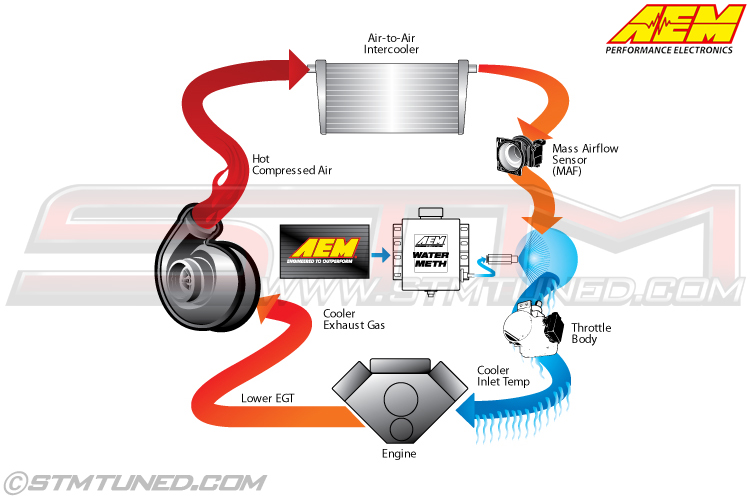

Water/methanol injection for forced induction (turbocharged or supercharged) gas-powered race engines is a proven means for effectively reducing engine inlet air temperatures and suppressing harmful detonation. This allows racers to reliably increase boost and advance ignition timing (without using high-octane racing fuel) for power gains of up to 20%. AEM's Water/Methanol Injection Systems utilize the most robust hardware combined with more advanced features than any other comparably priced water/methanol system.

The new AEM controller designs feature large, turn-resistant knobs and larger numbering to easily set accurate start and full activation points, with covered status LED and test buttons for added splash resistance. A plug is integrated into the controller housing for mating to the redesigned wiring harness's positive-lock connector. The Boost Dependent controller housing has a molded-in, barbed nipple to accept a boost hose and a wiring legend on the back. Both controller housings feature an easy to access integrated fuse and molded mounting tabs.

WATER/METHANOL INJECTION ADVANTAGES FOR GAS ENGINES:

Reduces Air Inlet Charge Temps:

The term "liquid intercooling" with water/methanol injection refers to a highly atomized mist of water/methanol that is injected into the airstream and begins to evaporate. As it does, this evaporative effect reduces air charge temps by as much as 100 degrees, and delivers a more oxygen-rich air charge.

Reduces Detonation (Knock):

Water absorbs heat, and methanol is a cool burning, anti-knock rated fuel. When combined and introduced into the inlet stream, they can effectively increase your vehicle's anti-knock index so you can reliably increase boost pressure and advance ignition timing using pump gas.

Reduces Carbon Deposits:

Modern vehicles fitted with Exhaust Gas Recirculation (EGR) devices for emissions control promote heavy carbon build up inside the air intake. This carbon build-up can create 'hot spots' in the combustion chambers that can cause detonation. Water/methanol injection has a 'steam cleaning' effect that reduces this carbon build up, and in some cases can increase fuel economy.

Please review full product info at aemelectronics.com

For track and racing use only.

|

|

|

STM TERMS & CONDITIONS

|